Kian Tajhiz’s has gained technical independence in order to adopt a unique and optimized design that produces the most reliable transformers.

Our Offerings

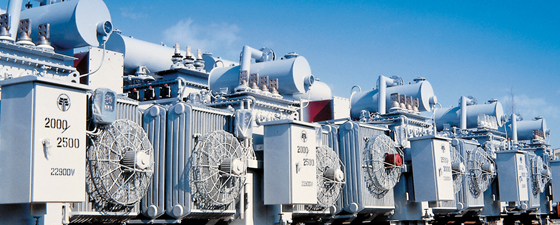

Oil Immersed Transformer

Kian Tajhiz’s currently exports its oil-immersed transformers to more than 25 countries all over the world.

Cast Resin Transformers

Kian Tajhiz’s cast resin transformer features a compact size and minimized power loss and noise by adopting the latest design techniques.

Oil Immersed Transformer

Description

Based on know-how accumulated over several years, Kian Tajhiz’s oil-immersed transformers have been supplied to various industries including semiconductor, steel work, and petrochemical. Further, as an outstanding and comprehensive solution provider, we respond to the demanding requirements of our customers by developing and manufacturing both eco-friendly and high-efficiency transformers.

Features

- Excellent short-circuit resistance

- Satisfies the various load conditions required by customers

- Low-loss step lap laminated core

- Uses latest insulation material with high short-circuit strength to realize high thermal capacity

- Cold steel sheet is used for radiating pipe to ensure a sufficient cooling effect and aesthetic exterior

- Compact, light, and low-noise transformer with standard efficiency and noise level which can be easily installed even in a small indoor or outdoor area

Panel type

- Specifications

50,000kVA or below, 66kV or below

- Radiating Structure

Manufactured with the thin, cold-rolled steel sheets containing a vertical oil path, where insulation oil can circulate; each radiating pipe is constructed of two cold-rolled steel sheets, which are parallel and have equal length.

The length of the radiating pipe is determined by the tank’s height. It is divided into a separate or all-in-one type depending on the welding method used.

Customized design is available by combining the radiating sheet in a variety of ways; the radiator can be separated for transportation.

Cast Resin Transformers

Description

Our cast resin transformers are certified by ISO and CESI, an international certification authority. In 2008, we obtained the coveted seismic and vibration test (Q-Class) certificate, proving once more that our quality management and technical competence are unmatched.

Features

- Self-extinguishing characteristics of epoxy significantly reduces the spread and effect of a fire, and the possibility of explosion is nearly non-existent

- Easy transportation and installation with simple structure

- No toxic substance (oil or gas) discharged

- Extended lifetime Adopts a higher class epoxy resin

Epoxy Resin: uses H class epoxy resin, which is higher than the standard F class, as the main insulation material of the mold transformer to control thermal aging and extend the overall lifetime of the transformer by three-folds.

- High stability and durability with strict quality management

Winding structure: when the radial build (RB) of the high-pressure winding is large, the temperature difference between the center and the surface of the winding gets higher, then crack in the winding may cause a partial discharge. Therefore, when the RB is large, an air duct is inserted making the RB thinner, then the temperature difference between the center and the surface is reduced and cracking is prevented.

When the air duct is inserted, the electric field distribution of the high-pressure winding becomes stable and the withstanding voltage becomes more resilient against external surge.

Casting process quality management: By strengthening quality management and interim examination of the casting process which determines the electrical and mechanical quality of the windings, the quality of casting by batch is checked (* Testing is required for checking how high the temperature is required to be for transiting from the solid glass-like elasticity of the solid polymer to the flexible rubber-like elasticity as well as checking the chemical combination status of the epoxy resin and process stability.)

By adopting the latest analysis technique, the transformer can be operated under severe conditions. Satisfies the customers by resolving various failures and anomalies, which may occur in operation on site, through technical analysis and visiting the site when customers request after-service.

Installation Site

- Where the installation condition is limited

- Where fire prevention is required (Flame Retardancy)

- Where customers request reliability

- Transformer for special load: Inverter, converter, UPS system, electric arc furnace, variable transmission drive, electric welding device, industrial process control

- Where the eco-friendly and environment-resistance is necessary

Common and public facilities: Condominiums, hotels, studio apartments, shopping malls, hospitals, and other public facilities

Manufacturing factories: Automobile factories, semiconductor factories, and chemical factories

Ships and renewable energy facilities: LNG ships, electric propulsion ships, and wind power generation systems

Special areas: Power plants (nuclear, water, fire, wind, and tidal), airports, subways, container cranes, and tunnel excavation work

Specification

| Classification |

Description |

| Installation Area |

Indoor |

| Rated Voltage (kV) |

1st Voltage and Tap Voltage |

23.9F-22.9R-21.9-20.9-19.9 |

6.9F-6.6R-6.3-6.0-5.7

3.45F-3.3R-3.15-3.0-2.85 |

| 2nd Voltage |

6.6/3.3 |

0.38-0.22 |

0.22-0.11 |

0.38-0.22 |

| Phase |

3ph |

3ph |

1ph |

3ph |

| Standard Wiring |

△-△ |

△-Y |

1ph, 3-wiring |

△-Y |

| Rated Capacity (kVA) |

|

75 |

75 |

75 |

| |

100 |

100 |

100 |

| |

150 |

150 |

150 |

| |

200 |

200 |

200 |

| |

300 |

300 |

300 |

| |

500 |

500 |

500 |

| 750 |

750 |

|

750 |

| 1,000 |

1,000 |

|

1,000 |

| 1,500 |

1,500 |

|

1,500 |

| 2,000 |

2,000 |

|

2,000 |

| 3,000 |

3,000 |

|

3,000 |

| 4,000 |

4,000 |

|

4,000 |

| 5,000 |

5,000 |

|

5,000 |

| 7,500 |

|

|

|

| 10,000 |

|

|

|

| 15,000 |

|

|

|

| 20,000 |

|

|

|

| Frequency |

50, 60Hz |

| Insulation Class |

Primary : F, B Secondary : F, B |

| Increase in Winding Temperature |

Primary : 100°C, 80°C Secondary : 100°C, 80°C |

| Standards |

IEC, ANSI, NEMA, DIN, JEC |

| Dielectric Strength / Voltage Class |

20kV |

6kV |

3kV |

0.4kV or below |

| Power Frequency Withstand Voltage |

50kV |

20kV |

10kV |

3kV |

| Impulse Withstand Voltage (BIL) |

95/125kV |

60kV |

40kV |

- |